ALIMENTAÇÃO COM CORRENTE ALTERNA MONOFÁSICA 220V.

HG 50, Chamber volume of 60 L, Effective useful volume of 50.2 L

HG 80, Chamber volume of 85.1 L, Effective useful volume of 76 L

ALIMENTAÇÃO COM CORRENTE ALTERNA TRIFÁSICA 400V.

HG 113, Chamber volume of 131.7 L, Effective useful volume of 108 L

HG 133, Chamber volume of 152.2 L, Effective useful volume of 129 L

Devices with heater in the chamber

Effective vacuum

Mobile use

Heating

Top technology

All HMC steam sterilizers are produced in modern manufacturing facilities using state of the art technology and are TÜV certified. All devices meet the EC Pressure Equipment Directive and the current European regulations and bear the CE label.

Twice as safe

The locking system is coupled with a pressure and temperature monitoring system. Sensors monitor the lid state. Unintended opening under pressure not possible by design. The opening temperature (important for liquid sterilization) can be preset to between 60-97 °C (temperature dependend lid opening). No electronics and no moving parts in the lid, therefore reliable and trouble-free. Maximum service life!

Selection criteria

| Legal: |

|

|

| Application: |

|

|

| Structural: |

|

|

| Occupational health and safety: |

|

|

| Economics: |

|

Easy of use

The low loading height and the smooth surface make for easy loading and unloading.

There are no obstructing locks or edges on which the baskets could catch.

Illuminated display

The clear, bright membrane display shows all important parameters at a glance and is self-explanatory. Simple menu navigation allows adaptations for customized program. 12 programs are available, divided into 4 groups with 3 sub-groups each.

The optimum for each load.

The timer function lets you start the program with a turn-on delay in order to have it end at a precisely defined time.

GREEN OPERATION

Save resources

Green operation

Top-quality materials are used to manufacture the high-tech chambers with a reduced mass. Result is a long service life and short heating and cooling times. Ideal energy efficiency.

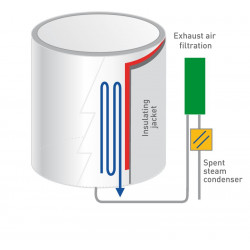

Spent steam condenser

The innovative spent steam condensation system, highly efficient and matched to the energy and volume, prevents odor and steam pollution. This ensures a pleasant indoor climate in the environment of the device.

The HG series: Sophisticated functionality

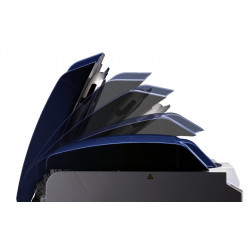

The HG series devices are divided into working capacities of 50/80/113/133 litres and set standards with regard to comfort and safety. The user will be pleased by the extremely simple operation using the self-explanatory membrane keyboard with LED program display. The locking systems for both series consist of a motorized lid and an innovative locking system. The lid opens at the push of a button: first it only opens a safe gap in order to relieve the remaining pressure, then automatically and finally all the way.

Unintended opening is impossible. The user is protected against escaping steam.Starting the program as well as opening and closing of the autoclave chamber are triggered via a single key. The lid is lowered gently and locked automatically. The program starts automatically.

The lock operating principles

HG 50/80

The V-seal gasket is activated by pressure. It is embedded in the edge of the lid, and swivelled up and out of the way upon opening to protect it against damage during loading and unloading.

HG/HGS/HGD 113/133

The double V-seal gasket seals equally well against vacuum and pressure. It is embedded flush in the edge of the chamber and therefore protected against damage during loading and unloading. The seals for both types can be replaced by the user themselves in just a few minutes.